The zero-waste movement has spread rapidly in the global fashion industry.

The fashion industry is one of the leading polluters, generating around 10 percent of global carbon dioxide emissions each year, according to the Intergovernmental Panel on Climate Change.

“I know zero-waste fashion is growing in brands like Nike and Zara, who have released products that reuse materials, but I’ve never bought them,” said Yoon Na-ra, who has been trying to live a zero-waste life for the past few years.

Yoon is one of over 800 people in the chat room “People Who Dream of a World Without Trash,” who strive for zero waste and a clean environment.

“To begin with, I don’t buy new clothes now because I rarely shop. I remember zero-waste fashion brand clothes being expensive and they weren’t my style,” said Yoon. “In my opinion, those who practice zero-waste like me try not to buy clothes and when they do, they buy it secondhand or at a vintage shop. Of course, buying from a zero-waste brand could be a possible solution. If the brand has the design and material that I want, I am willing to give them a try.”

While upcycling and recycling materials to make clothing have been the focus of major fashion companies trying to reduce waste, some South Korean fashion brands have focused on zero-waste design, the selection of zero-waste materials and production on demand to help conserve the environment.

The fashion industry is one of the leading polluters, generating around 10 percent of global carbon dioxide emissions each year, according to the Intergovernmental Panel on Climate Change.

“I know zero-waste fashion is growing in brands like Nike and Zara, who have released products that reuse materials, but I’ve never bought them,” said Yoon Na-ra, who has been trying to live a zero-waste life for the past few years.

Yoon is one of over 800 people in the chat room “People Who Dream of a World Without Trash,” who strive for zero waste and a clean environment.

“To begin with, I don’t buy new clothes now because I rarely shop. I remember zero-waste fashion brand clothes being expensive and they weren’t my style,” said Yoon. “In my opinion, those who practice zero-waste like me try not to buy clothes and when they do, they buy it secondhand or at a vintage shop. Of course, buying from a zero-waste brand could be a possible solution. If the brand has the design and material that I want, I am willing to give them a try.”

While upcycling and recycling materials to make clothing have been the focus of major fashion companies trying to reduce waste, some South Korean fashion brands have focused on zero-waste design, the selection of zero-waste materials and production on demand to help conserve the environment.

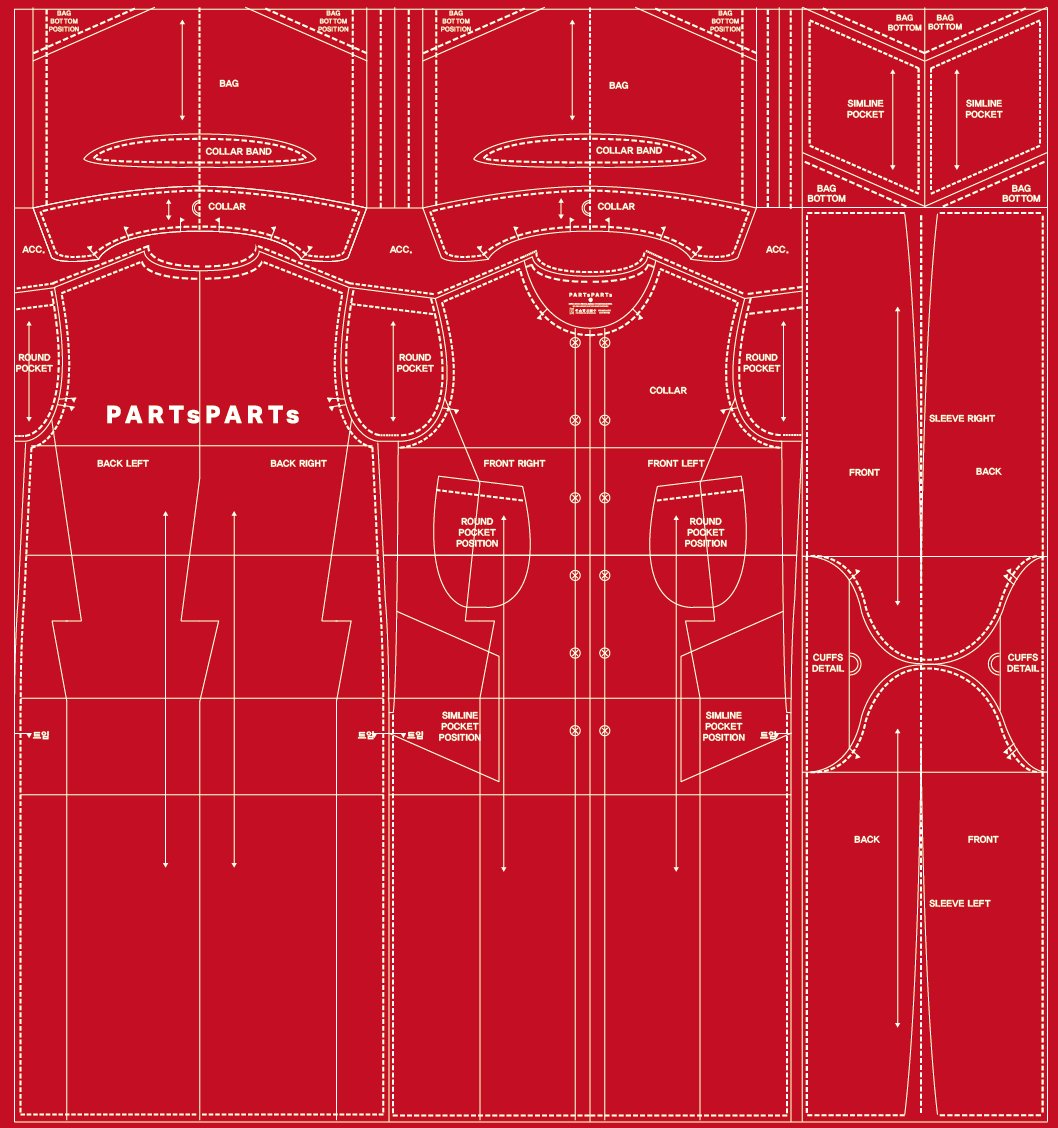

One of those promoting zero-waste design is veteran fashion designer Im Seon-ok, whose collection for PARTsPARTs was shown on Saturday, the last day of Seoul Fashion Week.

Im’s hobby is poking around secondhand stores, and her joy at finding unique aesthetics in the intricate mess led to her interest in reusing resources and eventually reducing waste.

“In 2010 when I launched PARTsPARTs, I was skeptical about the consumption of fashion cycle,” she said. By this point, she has had more than 15 years of experience as a designer of local and international collections.

“I had a clear goal of making a lasting brand that uses only one material to have a unique brand identity and reduce waste of resources,” Im told The Korea Herald.

“Trends in fashion come and go quickly, and if people in the industry respond only to sales, large amounts of raw and secondary materials are thrown away without ever being used. These are great materials, and I think it is up to designers to design solutions to use these materials,” said Im.

Zero-waste is a key element that governs the creation process at PARTsPARTs, whose name illustrates that the combination of parts makes up the whole. Clothes are made by using new neoprene fabric and high-heat compression to attach the different parts together. The process is aimed at minimizing waste.

“Neoprene is a material usually used in diving suits, but the new neoprene that we developed is much lighter and can retain warmth better. When the material is cut, there are no loose strings so there is no need to overlock. Also, local seamstresses are aging, making it necessary to find a new method to replace sewing,” said Im.

By carefully laying out the pieces of the clothes like a puzzle, PARTsPARTs makes it possible to use the entire fabric -- nothing goes to waste. PARTsPARTs also recycles the few resulting scraps to make smaller merchandise, including masks for COVID-19, further reducing waste.

“The entire production process is also a design process. This production process and the use of a single material allows resources to not be wasted before the design process because of the trend or the season,” she said.

While Im is on the lookout for new, inventive materials that could help with zero-waste efforts, one emerging technology for zero-waste production that has grabbed Im’s interest is 3D printing. 3D printing is seen in the fashion industry as a way for customers to print clothing exactly to their measurements and the process also generates zero waste.

“3D printing can be a possible solution (to reducing waste), so can a material revolution that is coming soon,” said Im.

Another brand that focuses on the reduction of waste at the design level is 000gan. The two major ways it does this are zero-waste design and making its clothes on demand.

“By using zero-waste design, we design to minimize raw material waste from the creation level,” said Shin Yoon-ye, CEO of 000gan. “When we make clothes, we make them like a puzzle so that the leftover cloth is minimized. Also, by collaborating with companies, we are developing zero-waste and upcycling design products.”

Shin also runs the online platform Withgoods, where customers can order products to be made through the waste reduction process, resulting in no waste or leftover inventory.

“I learned about Changsin-dong, Seoul, when I was an art teacher. Seeing the large amount of leftover cloth being thrown away by the sewing factories, I felt there was a problem and wanted to solve the situation,” said Shin. “I feel people’s interest in the Korean zero-waste market is growing and more design companies are joining in. With more public interest in environmental issues, it will only grow further.”

Shin also rebutted the popular conception of zero-waste clothes as expensive and low in quality.

“Although the effort needed to make zero-waste clothes can lead to higher prices, the cost of raw materials can be saved so the final price doesn’t differ much from non-zero-waste products. The quality doesn’t differ as well,” said Shin.

By Lim Jang-won (ljw@heraldcorp.com)

-

Articles by Lim Jang-won

![[From the Scene] Monks, Buddhists hail return of remains of Buddhas](http://res.heraldm.com/phpwas/restmb_idxmake.php?idx=644&simg=/content/image/2024/04/19/20240419050617_0.jpg&u=20240419175937)

![[Graphic News] French bulldog most popular breed in US, Maltese most popular in Korea](http://res.heraldm.com/phpwas/restmb_idxmake.php?idx=644&simg=/content/image/2024/04/18/20240418050864_0.gif&u=)

![[From the Scene] Monks, Buddhists hail return of remains of Buddhas](http://res.heraldm.com/phpwas/restmb_idxmake.php?idx=652&simg=/content/image/2024/04/19/20240419050617_0.jpg&u=20240419175937)

![[KH Explains] Hyundai's full hybrid edge to pay off amid slow transition to pure EVs](http://res.heraldm.com/phpwas/restmb_idxmake.php?idx=652&simg=/content/image/2024/04/18/20240418050645_0.jpg&u=20240419100350)

![[Today’s K-pop] Illit drops debut single remix](http://res.heraldm.com/phpwas/restmb_idxmake.php?idx=642&simg=/content/image/2024/04/19/20240419050612_0.jpg&u=)