[Editorial] Korea’s slow pace in chip race

Samsung likely to get greater-than-expected chip subsidy from Washington; Seoul lags far behind

By Korea HeraldPublished : March 20, 2024 - 05:31

The news reports last week that Samsung Electronics would likely receive over $6 billion in subsidies from the US government for expanded investments present mixed implications for both the South Korean government and the chipmaker.

It is certainly a positive development for Samsung to receive the largest amount of subsidies as a non-American company. Given that the subsidies would amount to a range between $2 billion and $3 billion, the scale of US support tops expectations by a wide margin.

The US Department of Commerce will soon announce details about the subsidies under the US CHIPS and Science Act, Bloomberg reported. The act was legislated in 2022 to encourage semiconductor firms like Samsung to build factories and produce chips in the US. Samsung is currently building a chip foundry plant in Taylor, Texas, a project that will cost $17 billion in investment.

What is notable is that the amount of subsidies for Samsung outpaces that for TSMC, the world’s biggest contract chipmaker. It is reported that the US government will give more than $5 billion in federal grants to the Taiwanese chipmaker for setting up a plant in Arizona.

Some experts hold a view that the greater amount of subsidies, if confirmed, would provide a stronger foothold for Samsung to compete with TSMC, which carved out a 61.2 percent share in the contract-based chip manufacturing business in the fourth quarter. Samsung’s share stood at 11.3 percent.

It is speculated that the US government might have given high marks to Samsung for its versatile capabilities ranging from memory chips to design and packaging, a unique position in contrast with TSMC focused largely on the foundry manufacturing business.

The greater-than-expected subsidies, however, could work as a double-edged sword for Samsung. With extra money, Samsung could invest more in chipmaking technologies and facilities in a bid to narrow the gap with TSMC.

The additional subsidies could also be used to pay for rising costs to secure raw materials and set up facilities. Samsung reportedly faces the challenge of dealing with soaring costs caused by the US inflation in building the foundry plant in Taylor. One estimate puts some 30 percent increase in the construction cost for the Taylor plant.

However, the US government is likely to put more pressure on Samsung to make additional investments on American soil in return for the greater US federal grants. Samsung might have to map out specific plans for expanded investments under tight deadlines, as well as find ways to meet more conditions likely to be attached to the fund.

Another cause for concern is Samsung’s factories operating in China as the US limits to 5 percent the expansion of semiconductor manufacturing capacity in foreign countries of concern for companies over a 10-year period that receive funds under the CHIPS Act. The countries of concern are China, Russia, Iran and North Korea, and if Samsung, for instance, violates the rule, it has to return the entire funds.

Meanwhile, the Korean government is required to review its stalled support policies for the critical semiconductor industry, which is fast evolving in tandem with the advances in generative AI technology. As semiconductors power a wide range of products and solutions, governments across the world are sparing no effort and money to nurture and bolster their home-grown chip industries.

But the Korean government finds it difficult to set aside massive subsidies and provide big tax breaks to Samsung and other local chipmakers regarding semiconductor investment, mindful of possible criticism about favoritism toward conglomerates.

It is also regrettable that a web of complex regulations makes it extremely difficult to build chip-related factories in a speedy fashion, partly because lawmakers remain reluctant to pass laws aimed at lifting such cumbersome rules for the semiconductor industry.

-

Articles by Korea Herald

![[Grace Kao] Hybe vs. Ador: Inspiration, imitation and plagiarism](http://res.heraldm.com/phpwas/restmb_idxmake.php?idx=644&simg=/content/image/2024/04/28/20240428050220_0.jpg&u=)

![[Herald Interview] Mom’s Touch seeks to replicate success in Japan](http://res.heraldm.com/phpwas/restmb_idxmake.php?idx=644&simg=/content/image/2024/04/29/20240429050568_0.jpg&u=)

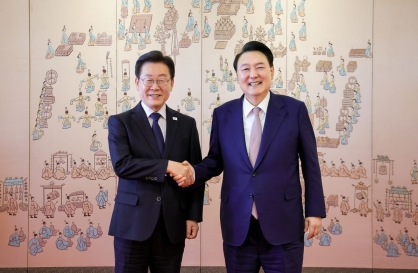

![[News Focus] Lee tells Yoon that he has governed without political dialogue](http://res.heraldm.com/phpwas/restmb_idxmake.php?idx=644&simg=/content/image/2024/04/29/20240429050696_0.jpg&u=20240429210658)

![[Today’s K-pop] Seventeen sets sales record with best-of album](http://res.heraldm.com/phpwas/restmb_idxmake.php?idx=642&simg=/content/image/2024/04/30/20240430050818_0.jpg&u=)